With special glass into a sustainable future

Glass has been with us for a very long time. Mankind has been burning sand into this transparent and flexible material for 9,000 years. But it is only through the rapid development of the materials industry over the past 100 years that glass has penetrated all areas of life. As quartz glass, it offers extraordinary applications in industry and research, for example in the fields of communications, medicine, IT, the environment, or space. It has thus paved the way for many high-tech applications. Metallic glasses, as amorphous metals are also called, are just as versatile. Here, too, Heraeus develops products and solutions whose applications extend to special processes and materials for glass production in other industries. We would like to briefly introduce all of them here.

Fused silica solutions from the earth to the stars

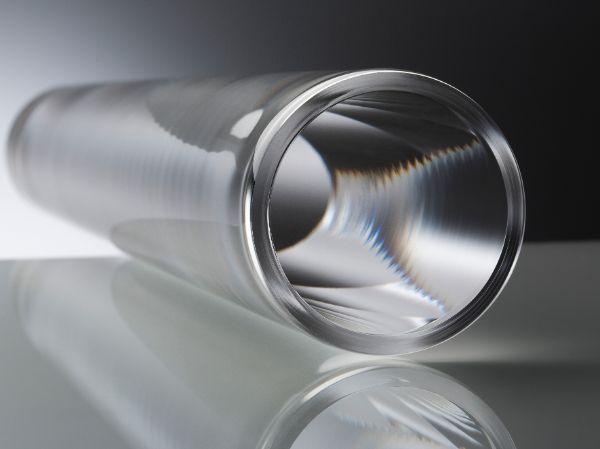

Fused silica is characterized, among other things, by its high chemical purity, temperature resistance, and light transmission from the ultraviolet to the infrared range. The two business units Heraeus Conamic and Heraeus Comvance produce the material. While natural quartz glass is still produced quite simply by melting sand, fused silica is produced by burning and separating condensate from a gaseous intermediate product. This enables particularly high purity.

Heraeus Comvance is the specialist for high-speed Internet. Its fused silica cylinders are the basis for the fiber optic expansion of the global data network. Small incisions, short operation times, and fast recovery are the advantages of minimally invasive laser surgery. Heraeus Conamic supplies the raw material for the appropriate fused silica fibers to guide the laser into the body. The Global Business Unit also ensures that semiconductors for today's all-important microchips function properly. Process tubes made of fused silica ensure that the critical coating process for semiconductors runs optimally.

Another important field, not just since the Corona pandemic, is the UV disinfection of water or air. Fused silica for high-purity lamp tubes from Heraeus Conamic enables UV solutions from the Global Business Unit Heraeus Noblelight to reliably kill bacteria or viruses.

Fused silica for space exploration is a high-altitude product. Since the Apollo 11 mission in 1969, for example, a laser reflector with 100 quartz glass prisms has been on the moon, which can still be used today to reliably measure the distance between the earth and the moon.

Metallic glasses with ice-cold advantages

Flash freezing can show amazing results. Metallic melts give rise to metallic glasses, also known as amorphous metals or alloys. The result is material properties that are normally mutually exclusive, such as high strength combined with high elasticity. This makes such glasses a sought-after material for many industries such as medical technology, automotive, robotics, sensor technology, or aerospace.

Quartz glass makes it more beautiful and safer

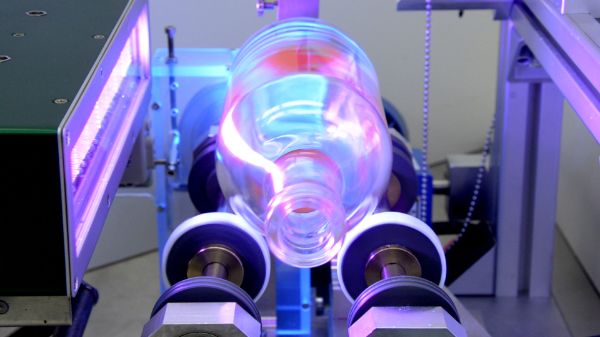

UV lamps and systems or infrared emitters from Heraeus Noblelight with fused silica components from Heraeus Conamic are used in glass processing in many industries. In this way, perfume bottles get their attractive look through decorations and coatings . Infrared emitters help to bond the seals of car windows securely, adapting perfectly to manufacturing cycles. In addition, infrared technology also made its way into medical technology a few years ago. Here, the fact that they can also be used in cleanrooms and under vacuum is particularly advantageous. For example, glass ampoules for vaccines can be made germ-free and unbreakable.

Precious metal shines in glass production

What would our everyday life be like without modern glass? Unimaginable. Glass is our daily companion and enriches our lives - whether as cover glass on a smartphone display, as a lens in a camera, or as packaging for vaccines. High-quality technical and medical glass requires precious metals such as platinum and rhodium in its manufacture. These precious metals and their alloys can be used to process innovative, sophisticated types of glass and they retain their characteristic properties – such as maximum flexibility for foldable displays or break resistance as a glass ampoule. Without precious metals, with their durability and high melting point, it would be impossible to process and manufacture such cutting-edge glass. The specialists in the Global Business Unit Heraeus Precious Metals offers the right products and services for all relevant precious metals for glass production.