Customized metallization solutions for solar cells

The need for decarbonization is greater than ever. Ambitious global targets for reducing CO2 emissions can only be achieved by expanding renewable energies. In addition, geopolitical aspects are increasing the pressure to become independent of fossil fuels. Solar power is an indispensable resource for clean energy – today and in the future. Heraeus Photovoltaics, a global leading manufacturer of metallization pastes for solar cells, is developing advanced products for the photovoltaic industry.

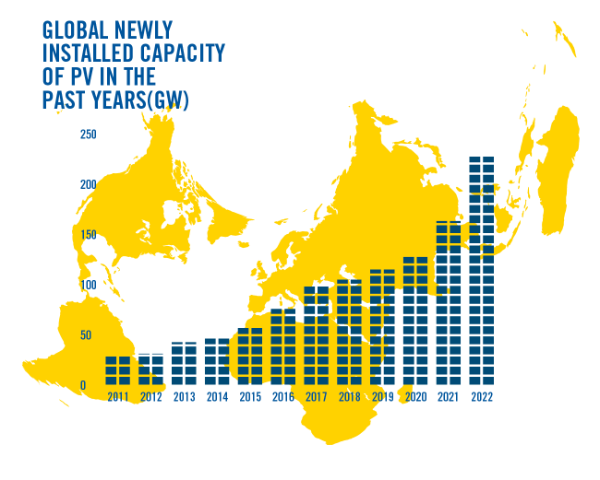

Solar, wind, hydro and geothermal are the most widespread renewable energy sources – with solar being the most abundant. According to the United Nations, the rate at which solar energy is intercepted by the earth is about 10,000 times greater than the rate at which humankind consumes energy. In addition, the International Energy Agency sees photovoltaics (PV) as the lowest-cost option for new electricity generation in most parts of the world. For 2023, Heraeus Photovoltaics estimates newly installed photovoltaic capacity to reach 280-330 Gigawatt globally.

China is the major player in the PV industry

Renewable energy generation has grown steadily in recent years, this is especially true for photovoltaics. According to statistics from Blackhawk PV, investments in photovoltaic capacity in China have exceeded 800 billion Yuan (106 billion Euro) in 2022. During the past three years, the production of PV silicon materials, silicon wafers, cells and modules has also seen enormous growth.

From 2021 to 2022, the newly installed capacity of solar power generation in China has risen by nearly 60 percent. While China used to focus much on scaled centralized power stations, the trend over the past two years has moved towards distributed and concentrated PV installations for both industry and private buildings. Distributed systems are expected to dominate total PV installations in China soon. Competition in the Chinese photovoltaic industry has intensified due to a growing number of new market entrants and changes in customer demand for more advanced and tailored technologies.

Our contribution: High performance through innovation

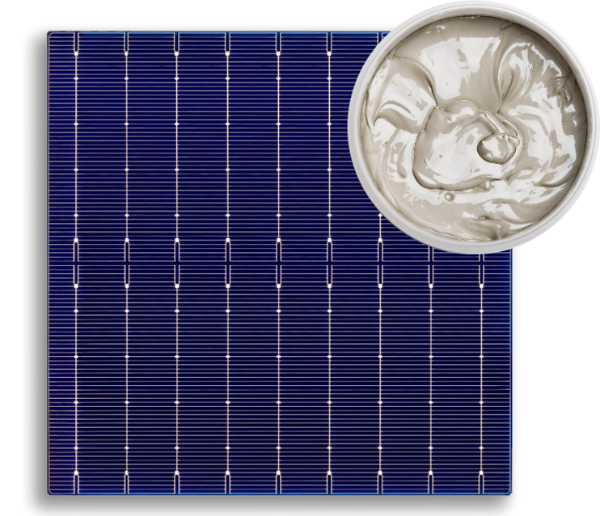

The PV industry is facing a highly dynamic market environment. The industry is working on improvements for the existing technology and to make solar modules more efficient. Heraeus Photovoltaics manufactures metallization pastes for solar cells and is driving innovation in this field. Silver paste is one of the core auxiliary materials for PV cells. At the same time, it is one of the most important materials to improve efficiency and to balance overall cost at cell level. Silver paste accounts currently for about 10 percent of the total cost of solar cells. Therefore, the PV industry is committed to improve the silver paste’s utilization rate and to use it as efficiently as possible for each solar cell – not only for sustainability reasons.

Each solar cell producer has a unique cell design and manufacturing process. Adapting the metallization pastes to the customer’s individual manufacturing process ensures optimum results. Heraeus uses state-of-the-art laboratories located in Shanghai and Singapore for the customization process. The challenge is to find the best match between paste formulation and customer requirements, so that the full potential can be realized for each customer.

In a global context, where countries are striving to achieve carbon neutrality, the demand for PV will continue to grow. This is also driven by the Chinese government’s goals for decarbonization and carbon neutrality. In this dynamic market environment, Heraeus Photovoltaics continues to focus on research and development and solutions for individual customer needs, contributing to the provision of more sustainable energy for future generations.